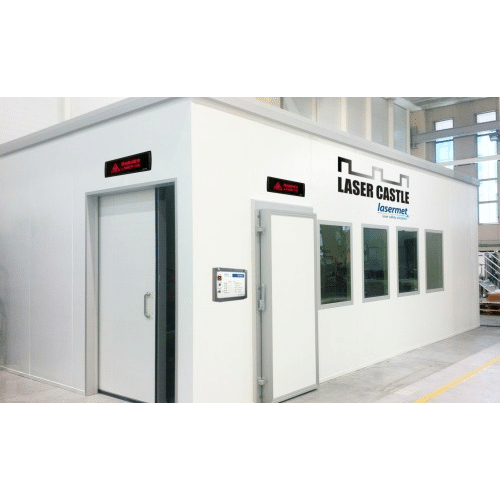

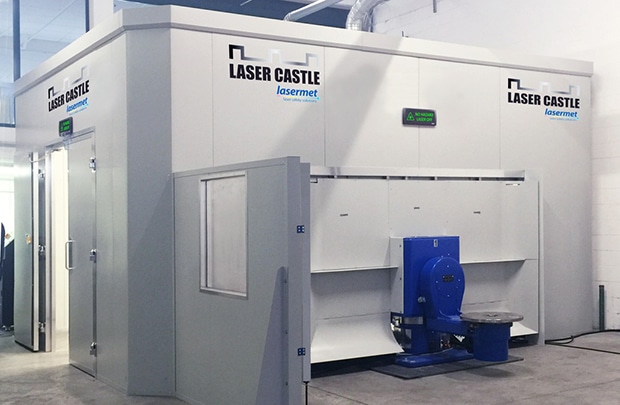

Lasermet’s Interlock® Control System is included with the Laser Castle Passive Laser Safety Cabin, which includes LED Warning Signs, an Interlock® Controller, Interlock Switches and door maglocks, Audio Alerts (optional), and an HD CCTV System. The Laser Jailer system is included in an upgraded version of the Laser Castle to create an Active Guarding Enclosure.

There is space for fume extraction systems and a lighting package, making this a low-cost and simple method of enclosing the laser system that complies with international laser safety standards.

The system consists of an enclosure made of panels certified to the Laser Safety Standard EN IEC 60825-4 and constructed from passive laser safety compliant material. The enclosure is formed by connecting the panels (including a roof).

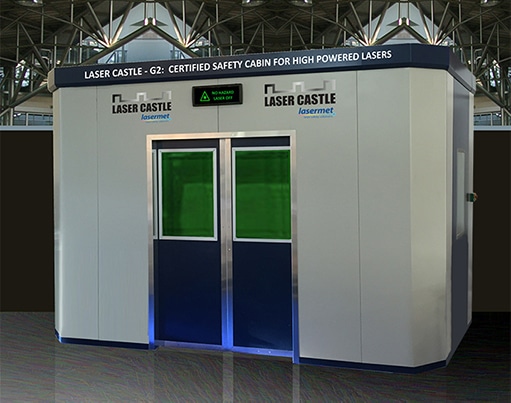

DOORS

Doors made of our special laser blocking panels provide access into the enclosure. There are several door options available, including single or double sliding doors that provide maximum access while taking up the least amount of space. Doors with single or double hinges are also available.

ILLUMINATED WARNING SIGN

Above the door, a dual message in dual color LED laser warning sign indicates the status of the laser as controlled by the Interlock® controller. The LED sign, which includes the laser warning triangle, reads “Danger Laser On” in red when the laser is turned on and “No Hazard Laser Off” in green when the laser is turned off.

HD CCTV MONITORING SYSTEM

With the enclosure, a CCTV system can be installed. Inside the enclosure, one or two remotely controlled cameras transmit video to the video monitor(s) outside the enclosure. When two cameras are installed, the video monitors can be controlled by a joystick controller to display the view from either camera.

ELECTRICAL SYSTEM

Inside the enclosure, the electrical wiring is routed through containment channels. Lasermet created, manufactured, and installed the Laser Castle and laser safety Interlock® systems.

EASY RELOCATION

Because of its lightweight, modular design, the enclosure can be quickly disassembled, moved, and reassembled. The standard sized panels allow the enclosure size to be changed as well. For today’s rapidly changing environment, this is an ideal, flexible, lightweight solution.

ACTIVE GUARDING LASER JAILER® UPGRADE

By specifying the Laser Jailer® Active Laser Guarding System, the passive cabin can be upgraded to an active laser safety cabin. To detect high powered laser beam strikes, this patented modular system has active detector panels covering the internal walls and roof of the cabin. If this happens, Lasermet’s fail-safe technology isolates the laser safety input in under 50ms. This laser termination signal is received by the laser machine, and the laser radiation is terminated.

APPLICATIONS

The cabins are ideal for laser welding robots that need to be contained because they typically operate with 4kW lasers. Higher power lasers, such as 10kW or 20kW, can also be accommodated.

LASER CASTLE INSTALLATIONS

The Laser Castle can be fully custom designed and built to suit your needs.

Compliance and Safety Standards

PEL RATINGS

The PEL ratings for the passive cabin are listed below.

| IRRADIATED AREA | PEL (T3) 10 S | PEL (T2) 100 S |

| 4 mm² | 310 MW/m² | 170 MW/m² |

| 2000 mm² | 3.1 MW/m² | 1.7 MW/m² |

SPECIFICATION TO THE LASER SAFETY STANDARDS ANSI Z136.1 AND IEC 60825-1

To meet the laser safety standards of ANSI Z136.1 and IEC 60825-1, the enclosure must include a safety Interlock® control system and appropriate warning signs, both of which are designed and manufactured by Lasermet.

COMPLIANCE TO EN ISO 13849-1 SAFETY OF MACHINERY: SAFETY-RELATED PARTS OF CONTROL SYSTEMS

Lasermet’s ICS-9 and ICS-7-OEM Interlock® Control Systems meet ISO 13849-1 Performance Level e (PLe) and are ideal for achieving the required laser safety standard.

Control of Substances Hazardous to Health (COSHH)

FIRE

Early-stage fires can be easily extinguished using a water, CO2, dry powder, or BCF extinguisher.

SMOKE AND FUMES

Carbon monoxide and styrene gas are emitted when panels are burned. In comparison tests, the amount emitted is less than that emitted by wood and other traditional building materials. The smoke hazard caused by burning panels is similar to that posed by any other building, decorating, or packaging material.

CLEANING & MAINTENANCE OF PANELS

Fresh water from a hose or bucket can be used to clean the panels. Heat the water to 60°C. To remove heavy deposits, use a solution of fresh water and non-aggressive detergent, followed by a fresh water rinse.

CE CERTIFIED LASER BLOCKING PARTITIONS

We also sell CE-certified laser blocking partitions with or without doors, which can be used to divide a laser lab into two or more sections. These semi-permanent partitions are inexpensive and easy to install, eliminating the mess and difficulty of constructing a brick or plasterboard wall. As such, they provide an alternative to traditional methods of room division and can be easily undone if necessary. They can also be left as a permanent installation.

All laser safety partitions are tested and certified to EN 60825-4.