Laser Jailer® Active Laser Safety System

The objective of the Laser Jailer Active Guarding System is to reside a powerful laser beam inside a laser enclosure. The entire Laser Jailer System consists of an external passive laser safety enclosure with laser beam detector tiles all the way around. These active guarding panels are linked to the laser safety Interlock® System and function as a laser shield as well. In less than 50 milliseconds, any stray laser beam striking one of the tiles will isolate the laser.

The Laser Jailer Active Guarding System can be installed in almost any size laser enclosure, ranging from compact enclosures to large room-sized laser shelters with robot welding machines. The laser beam will then be effectively contained within the laser cabin by the fully operational laser barrier.

ACTIVE DETECTOR PANELS

A laser detector circuit, which is linked to the laser Interlock® System, is present in every Active Guarding Panel (also known as a detector tile).

The Interlock® Controller detects changes in the circuit properties and turns off the laser if a high power laser is aimed at any of the tiles inside the laser cell. The tiles are made to be readily replaceable after being hit by a high energy laser beam because of the incredibly high power of certain lasers. You can fold and overlap these sacrificial detector sheets to make them fit around equipment or into corners. To make replacement and repair easier, the tiles feature a straightforward connector at each end.

RETROFIT TO EXISTING ENCLOSURES OR CELLS

The Laser Jailer system can be added to an existing enclosure as it is a modular active laser protection system. High power, narrow beam lasers are incompatible with passive laser safety systems.

Utilizing fail-safe technology, the Lasermet active laser safety control system design is lightweight, adjustable, repeatable, and maintainable.

Active technology is used in the laser guard design, which makes it more affordable because it can lessen the need for some of the surrounding infrastructure’s strength and weight.

The Laser Jailer® Active Laser Guarding System ensures the laser is made safe if its beam is directed at the laser enclosure walls or ceiling.

BENEFITS OF ACTIVE LASER GUARDING

- Inherent Fail-safe technology

- Conforms to the design and laser safety standards

- Versatile, modular, scalable, lightweight

- Provides maximum protection

- Standard or custom-built design

- Easy to maintain

- Rapid availability

- Reduces building infrastructure

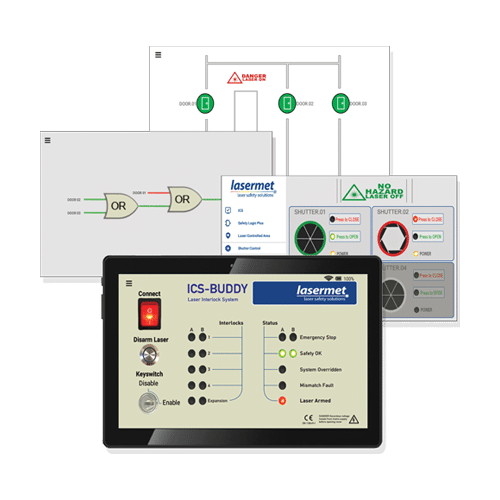

REMOTE MONITORING

This schematic illustrates how Lasermet’s Interlock® System, which offers the option of internet monitoring, can be integrated with the active safety system.

CONFORMANCE TO LASER SAFETY STANDARDS

The system is certified for and conforms with:

- BS EN IEC 60825-4 Safety of Laser Products

- BS EN ISO 13849-1:2008 Safety of Machinery – Safety-related parts of control systems

- Machinery Directive

- Low Voltage Directive

- Electromagnetic Compatibility Directive

Applications for Active Laser Guarding

For housing laser applications and activities involving laser drilling, laser welding, laser ablation, and laser cutting, the Laser Jailer is an efficient laser containment system. The aerospace sector, which uses laser machining, laser trimming, and laser turbine repair, is one of the industrial uses for the Laser Jailer. Laser containment is also a safety consideration for applications involving additive welding and laser additive manufacturing of complex parts.

The energy and nuclear industries now use lasers, along with the safety gear and training that followed. They use lasers to weld nuclear power plant pump components and even to perform underwater laser cutting and welding.

They can even be used to cut thick concrete slabs and for concrete scabbling during the dismantling of nuclear power plants.

LASER DANGERS TO BE CONSIDERED

The active laser guarding system from Lasermet is intended to stop laser-related injuries and deaths. Additionally, the surrounding infrastructure cannot be destroyed by lasers thanks to this high-speed active laser safety control system. This includes shielding the structure and its services from laser beam damage. More than just a basic beam blocking barrier, the Laser Jailer can be customized with any guard system the customer chooses, including active or passive laser blocking. Lasermet can also design and produce the entire custom laser cabin.

The active laser guard system’s rapid response is attained by detecting the laser hitting the active laser wall inside the laser room. If an unintended laser beam strikes any of the tiles, the Interlock® will swiftly disconnect the laser safety input in under 50 milliseconds. Subsequently, the laser will be deactivated, and the exact shutdown time will vary based on the specific laser machine in operation.

The Laser Jailer® is efficient across a wide range of laser wavelengths and finds application in material processing. It is utilized in various industries, including automotive, where it is employed in tasks like laser welding. Additionally, it is used in aerospace and renewables for activities such as laser hardening, laser profiling, laser surface cleaning, laser dressing, and laser machining.

Depending on the power of the laser being used, the medical and healthcare industries can use either passive or active laser safety enclosures for the laser machining of parts.

PASSIVE vs ACTIVE GUARDING

In comparatively brief periods, steel and even firebricks can be cut through with high beam power (>1kW) in small beam diameters. It is possible for even large beam diameters to shatter through concrete at very high beam powers (>5kW). For passive guards to be able to withstand the power density of the beams in these conditions, they must be placed sufficiently away from the laser aperture. Not all the time is this useful.

An active laser guard allows you to have a much smaller enclosure, as the required containment time is 50ms.

Ordering Options

To specify the Laser Jailer® Active Laser Guarding System you require, the following items must be addressed.

- Specification of the laser

- Intended use of the laser

- Dimensions and specification of the laser safety enclosure – a large laser enclosure may need estimated measurements for quotation purposes

- Identification of relevant safety interlocks -doors, switches, maglocks.

If you would like more information about the system, Lasermet is happy to help. If you’re uncertain what level of safety you need, we can set up a site visit.